Kunshan Guozheng Precision Mold Co.,Ltd

Add: No.396, Dujia Road, Zhoushi Town, Kunshan City

Email: info@kokusei-seimitsu.com.cn

Tel:+86 0512-57171088

Kunshan Guozheng Precision Mold Co., Ltd. was established in January 2016,

The company covers an area of more than 2200㎡.

and more than 70 professional and technical staff.

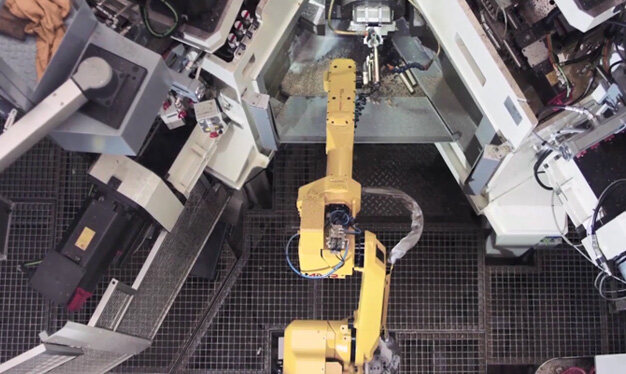

With foreign precision processing equipment and testing equipment.

It is currently a relatively large-scale enterprise in this industry in China.

The company has established strong partnerships with clients such as Sumitomo Electric, Suzuki, Hitachi, Hirose Electric, and Yazaki, supplying complementary products to renowned enterprises in the automotive, medical, marine, and other sectors.

It has gained full market recognition and been honored by numerous clients as an “Outstanding Supplier” and “Exemplary Enterprise in Kunshan's Mold Industry.”

High quality, short delivery time, and reasonable price are the eternal promises of the Guozheng people.

Although did not enter the manufacturing industry as early as some of the giants, this does not alter the fact that we are quickly catching up.

2016: Guozheng Precision Mold Co., Ltd. was established

2017: ISO 9001 2015 Quality Certification System

2018: Entering the field of injection molding and stamping mold manufacturing

2019: Establishment of subsidiaries: Sankyou Seiko

2020: Qualification for independent export trade

2021: Member of the Council of the Mold Association in Kunshan City, Jiangsu Province

2022: Expand Global Customer Base

2023: Expand into Automotive and Mechanical Transmission Components Industries

Efficient and precise product services, pursuit of customer satisfaction, innovative management, continuous improvement, and pursuit of excellence.

Our factory has passed international certification of ISO 9001: 2015.

We take pride in the strict quality control standards applied throughout each section of our production process.

And truly investing in understanding our clients' needs and working with them to deliver high-quality solutions, whilst continuously reviewing and improving the way we work.

Our dedicated team examines the product‘s quality, packaging, and threads, ensuring they are in optimal condition. We also adopt top-quality tools and effective inspection procedures to ensure your designs meet your requirements.